Mesfin G Woldetensay

Heriot-Watt University, Dubai campus, UAE

Title: Optimal Design and Operation of Gas Processing Plant (GPP) under Uncertain Upstream Conditions

Biography

Biography: Mesfin G Woldetensay

Abstract

Uncertainty is an inherent characteristic of any process. It may arise both from external and internal factors and has a profound effect especially for gas processing plant as its feeds are normally originated from upstream production facilities. Thus, the plant is usually subjected to continuous variations in upstream conditions, such as feed flow rate, composition, ambient temperature and pipeline pressure. These variations effects propagate throughout the plant and affect its normal operation. As a result, decision making for optimal operating conditions of an in-operating plant is a complex problem and it is exacerbated with changing product specifications and utility requirements. Moreover, the condition of feed composition is an important factor since it mainly determines what kind of process configuration to be employed for recovering natural gas liquids (NGLs). Besides, due to the number of process schemes developed for NGL recovery, it is usually difficult to select the best process scheme that can consolidate capital and operating costs within an acceptable range. In industrial practice, heuristic optimization approach based on trial and error have been employed to solve those problems. The main reason for such kind of decision is due to lack of systematic solution approach. As a result, aggressive decision may be preferred due to high profit expectation. However, this strategy will deteriorate the objective function and later leads to constraint violation. Therefore, a systematic method is required to evaluate the trade-off between profitability and reliability of holding the process constraints. The challenge here is how to find solution approaches that can incorporate all these uncertainties effect and enable us to make prior-decision for the in-operating plant.

Recent Publications:

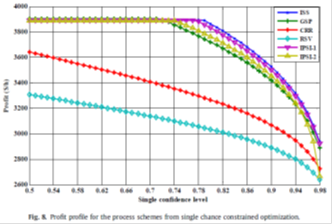

1. Mesfin, G & Shuhaimi, M. (2010).“A chance constrained approach for a gas processing plant with uncertain feed conditions”. Computers and Chemical Engineering,34(8),1256-1267.

2. Mesfin, G., Shuhaimi, M & Moonyong, L.(2012). “Analyzing the effects of uncertainties on the economic performance of a chemical process plant using a probabilistic optimization technique”. Computer Aided Chemical Engineering,30,832-836.

3. Mesfin, G., Khan M.S., Long, N.V., & Moonyong, L. (2012).“Studying the effect of feed composition variation on typical natural gas liquid (NGL) recovery processes”. Computer Aided Chemical Engineering,31,405-409.

4. Khan, M.S., Husnil,Y.A., Mesfin, G & Moonyong, L.(2012). “Modeling and Simulation of Multi-stream Heat Exchanger Using Artificial Neural Network”. Computer Aided Chemical Engineering,31,1196-1200.

5. Jung, Y., Long, N.V., Mesfin, G & Moonyong, L.(2012). “A Study of Complex Distillation Arrangements for Improved Depropanizing, Debutanizing and Deisobutanizing Fractionation of NGL”. Computer Aided Chemical Engineering,31,680-684.

6. Mesfin, G., Shuhaimi, M & Moonyong, L. (2013).“Techno-economic analysis of potential natural gas liquid (NGL) recovery processes under variations of feed compositions”. Chemical Engineering Research and Design, 91(7),1272-1283.

7. Mesfin, G., Shuhaimi, M & Moonyong, L.(2013). ”Profit optimization for chemical process plant based on a probabilistic approach by incorporating material flow uncertainties”. Computers and Chemical Engineering, 59,186-196.

8. Khan, M.S., Chaniago, Y.D., Mesfin, G & MOONYONG L.(2014).”Energy saving opportunities in integrated NGL/LNG schemes exploiting: Thermal-coupling common-utilities and process knowledge”. Chemical Engineering & Processing: Process Intensification, 82,54-64.

9. Khan, M.S., Lee, S., Mesfin, G & Moonyong, L.(2015).”Knowledge inspired investigation of selected parameters on energy consumption in nitrogen single and dual expander processes of natural gas liquefaction”. Journal of Natural Gas Science and Engineering, 23,324-337.

10. Mesfin, G. Shuhaimi, M., Yudi,S., Khan, M.S., Bahadori, A., Moonyong, L.(2015).“Risk-based optimization for representative natural gas liquid (NGL) recovery processes by considering uncertainty from the plant inlet”. Journal of Natural Gas Science and Engineering,27,42-54.

11. Park, J.H., Khan, MS., Andika, R., Mesfin, G., Bahadori, A., Moonyong, L.(2015). “Techno-economic evaluation of a novel NGL recovery scheme with nine patented schemes for offshore applications”. Journal of Natural Gas Science and Engineering, 27,2-17.

12. Tiong, C.C, Jobrun, N & Mesfin, G.(2016).” Retrofitting Options for Natural Gas Liquid (NGL) Fractionation Trains Using the Concept of Single Column Development”.Procedia Engineering,148,923-931.